Two wheels, two systems, one question: hooked or hookless? Since hookless (straight-side) rims became the standard in mountain biking around 2014, the technology has steadily moved towards gravel and road. Brands such as Zipp, ENVE and Hunt are building their latest wheelsets without ‘hooks’. Yet a significant portion of the peloton, including WorldTour teams, still ride on hooked rims and there are producers, such as Princeton CarbonWorks, which only produce hooked rims. The reason: it is a system choice, not an upgrade.

Where is the difference?

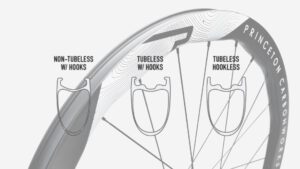

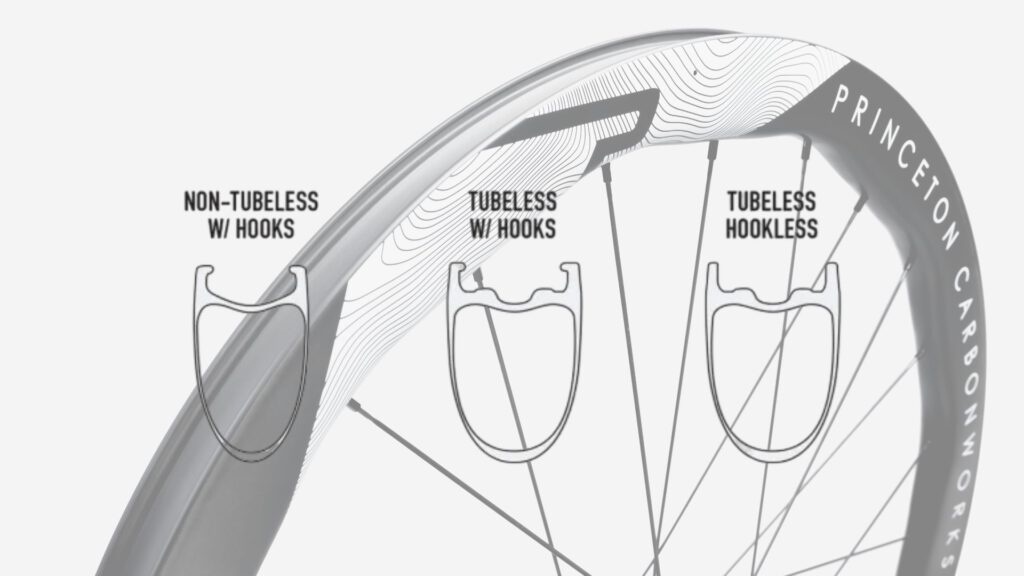

It revolves around the point where the tyre sits on the rim, known as the bead seat. A hooked rim has an inward projecting rim flange, the hook, at the top of the rim wall. That hook acts as a catch: when air pressure pushes out the tyre bead, the hook prevents the tyre from sliding off the rim. Especially at higher pressures (above 5 bar), this is a relevant safety margin.

A hookless rim has straight, vertical rim walls without a hook. The tyre is held in place by a combination of bead locks (small ridges on the rim bed) and the stiffness of the tyre bead itself. This works, but only if the tolerances are right: the bead seat diameter of the rim and the tyre bead must be exactly matched.

Briefly:

- Hooked = mechanical redundancy via the hook

- Hookless = Press-fit system, depending on size tolerances and tyre stiffness

Pressure: the real ceiling

The main limitation of hookless is the maximum tyre pressure of 72.5 psi (5 bar). This is not a conservative recommendation, but a hard limit from the ETRTO-standard. Above that pressure, the risk increases that the tyre bead will stretch and shoot off the rim, simply because there is no hook to act as a safety net.

For riders who ride 28 mm or wider at lower pressures (50-65 psi), this is not a problem. But those accustomed to tight 25 mm tyres at 90+ psi immediately bump into that limit. Hookless forces you towards wider tyres and lower pressure.

And there is a practical side to it: your floor pump is not always accurate to 0.2 bar. A deviation of 5-10% on your manometer can make the difference between 4.8 and 5.3 bar. With hooked rims, this is an inconvenience. With hookless, it's a risk.

Compatibility: not an afterthought

Hookless rims are tubeless only. That means: the tyre itself must be hookless-compatible, with a non-stretchable bead that meets the ISO 5775-standard. Mounting a standard clincher with inner tube on a hookless rim is not an option for everyday use. In an emergency, you can fit an inner tube, but the tyre should always be hookless-rated.

That limits your choice of tyres. Not every manufacturer offers hookless-compatible models, and the combination of rim width and tyre size has to be right. The ETRTO-guidelines from 2022/2023 stated, for example, that a 28 mm tyre should not be on a rim with 25 mm internal width, a combination that several wheel manufacturers and WorldTour teams were simply using at the time.

No, “just mounting another tyre” is not always plug-and-play with hookless.

Manufacturing: why manufacturers want hookless

From a wheelbuilder's perspective, hookless has distinct advantages. Hooked carbon rims require complex silicone moulds to form the hook. That soft tooling leads to variations in the dike of the carbon, making quality control difficult.

Hookless rims are produced with steel moulds (hard tooling). This provides:

- Better carbon compression and therefore a stronger, lighter profile

- Tighter dimensional tolerances on the bead seat

- Lower production costs (perhaps the main reason behind the choice for hookless)

- Thicker, impact-resistant rim flanges

The weight advantage is real but modest: about 10-20 grams per rim. Some brands, including ENVE, invest that weight saving partly back into thicker rim flanges to prevent snakebite punctures.

Despite production savings, hookless wheels are rarely offered significantly cheaper than hooked alternatives. The savings are mainly on the factory side.

Which discipline you cycle determines the logic

The question “hooked or hookless?” has no universal answer. The discipline dictates which system makes sense. There is a clear difference between road cycling, gravel and MTB.

Mountain bike and gravel: hookless is the dominant standard here. Tyres have large volume, are ridden at 20-45 psi, and the thicker rim flanges offer better protection from rocks and roots. The 5-bar limit is completely irrelevant at these pressure ranges.

Road: this is where the tension lies. The trend towards wider tyres (28-32 mm) and lower pressures makes hookless technically feasible. But the margins are smaller than off-road. The combination of higher speeds, longer descents and the importance of reliable bead retention in case of a puncture makes compatibility and pressure compliance more critical. And so then you sometimes see these excesses where a tyre suddenly pops off.

WorldTour: no single answer

The pro peloton is divided. Teams with ENVE-sponsorship, such as UAE Team Emirates, ride completely hookless. Their riders typically use 28-30 mm tyres at pressures between 52 and 65 psi, well within the limit. Teams on Zipp follow a similar path.

Other teams stick to hooked rims. The reason is pragmatic: maximum tyre choice freedom, the option to adjust pressure to course and conditions, and less dependence on compatibility lists.

The crash of Thomas De Gendt during the UAE Tour in 2024 led to increased attention to the system. Images showed a detached tyre and an entangled tubeless insert. Investigations by the UCI, Zipp and Vittoria concluded, however, that the incident was caused by a heavy impact (presumably a stone) that broke the rim. Once the structure of the rim had failed, no system, hooked or hookless, could keep the tyre in place.

In response, the UCI launched a review of hookless systems and stressed that teams should strictly follow the ISO 5775- and ETRTO-standards must follow. WorldTour teams have dedicated mechanics, selected tyre-rim combinations and set protocols.

The trade-off for you

You can of course use both rim types. But which one suits you? We list it again:

When is it best to choose Hookless rims?

You choose hookless rims as:

- You already ride tubeless with 28 mm or wider

- Your pressure stays below 5 bar

- You are willing to choose tyres from your wheel manufacturer's compatibility list

- You want to exploit the advantages of wide internal rim profiles

When do you choose hooked rims?

You choose hooked rims if you:

- You want maximum tyre choice

- You sometimes ride with inner tubes

- You prefer higher pressure (narrower than 28 mm, tight asphalt)

- You regularly switch between tyre brands or types

Hookless requires the whole chain, rim, tyre, pressure and tolerances, to be treated as one. With hooked rims, there is no such dependence on exact size tolerances and pressure limits.